According to reports, the sales of new energy heavy trucks in the first quarter of 2024 reached 10,954 units, a year-on-year increase of over 142%, outperforming the overall heavy truck market’s 12.99% year-on-year growth rate.

This means that new energy heavy trucks have strong market potential. Driven by the "dual carbon" goal and the official implementation of the National IV standards, the new energy heavy truck market will continue to grow rapidly.

Ouyang Minggao, an academician of the Chinese Academy of Sciences, said in February this year that the number of new energy trucks will increase significantly compared with new energy cars this year, and is expected to double compared with last year, with an overall number of more than 70,000 units. This year may be the year when the electrification of heavy trucks explodes, because equipment updates and logistics are all related to new energy heavy trucks.

However, the current penetration rate of new energy heavy trucks is still lower than that of new energy passenger vehicles. This is mainly due to the two "stumbling blocks" of operating costs and battery life. Improving the energy density and cycle life of battery cells is the best solution.

Based on market demand, REPT has made a strong breakthrough and seized the new high ground of electric heavy trucks in advance. From April 27th to 29th, REPT appeared at the 16th Chongqing International Battery Technology Exchange/Exhibition (CIBF 2024), launching a new electric heavy-duty truck product "324Ah lifepo4 battery cell", and delivering a sincere "work of concentration" to the market ".

REPT 324Ah battery cell advantages

Different from the general launch of new products, REPT's 324Ah lifepo4 battery cells are not only publicly released for the first time, but have also begun to be supplied in batches to two car companies, and can meet the needs of "commercial and storage sharing".

Obviously, REPT is unique in that it does not play with "technical concepts", but actually delivers new technological products that can be commercialized. Behind this is the REPT technical team’s painstaking research in the past two years and the support of sufficient client measured data.

REPT 324Ah battery cell performance advantages

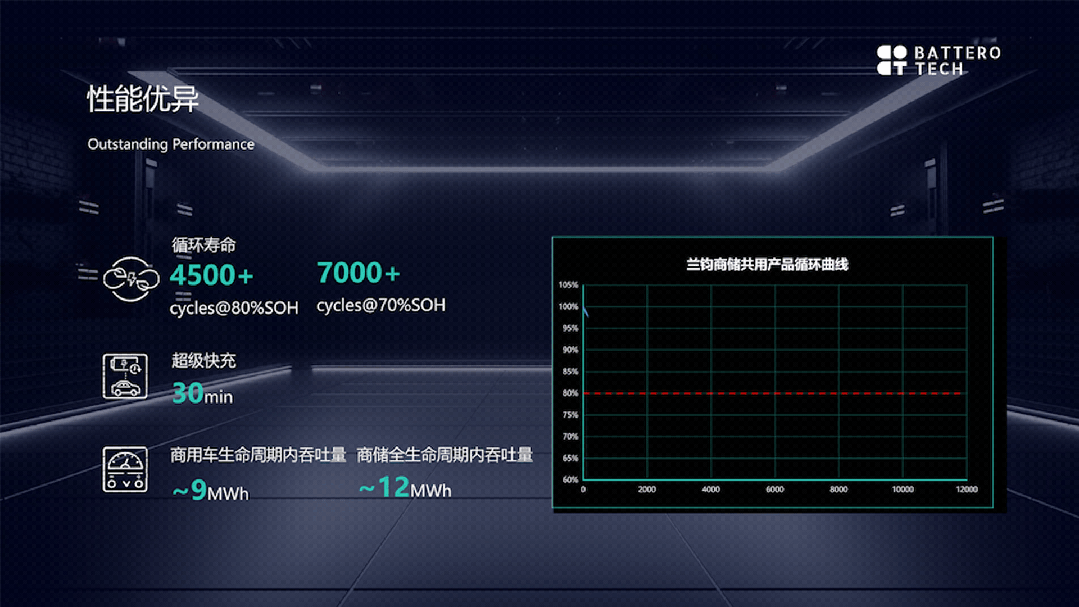

Specifically, in terms of energy density, REPT has achieved an energy density of 190Wh/Kg in 324Ah cells by applying technologies such as electrode improvement and cell current distribution optimization.

In terms of cycle life, REPT uses uniformly coated pure-phase cathode materials to effectively inhibit the dissolution of impurities, and the SEI film is toughened, which helps reduce interface side reactions and ensures that the product cycle life can reach 7000 times @70% EOL, stepcharge/1C.

As a result, commercial vehicles still have the value of new application scenarios to be released in the EOL stage; energy storage applications are expected to be extended to a 9,000-cycle commercial model based on the existing 7,000 cycles, and the remaining battery capacity at the end of the period is guaranteed to be 60%, and then Realize a new model of commercial and storage sharing and fully release the value of battery cells.

REPT 324Ah battery cell innovative design

In terms of safety, the 324Ah lifepo4 battery cell complies with the national energy storage safety standards and achieves multiple safety protections through innovative designs of materials, structural parts, and systems:

In terms of material innovation, the Lanjun 324Ah commercial and storage shared battery has a separator that uses heat-shrinkable self-closing technology. The surface of the separator is simultaneously coated with an alumina ceramic layer, which can effectively prevent small internal particles and lithium dendrites from piercing the separator. Has extremely high intrinsic safety;

It adopts an aluminum shell with a thickness of more than 0.6mm, and the top cover is connected and sealed by laser welding, with a pressure resistance of more than 1.0Mpa. It adopts a two-stage explosion-proof valve design. The explosion-proof valve opens in two stages, and one stage opens when the internal pressure is reached. The opening height is relatively high. Low, open the pressure relief when the internal pressure is too high to avoid the risk of explosion, and avoid short circuit and ignition caused by overlap of explosion-proof discs after multiple battery cell explosion-proof valves are opened at the same time in some extreme cases;

Using the large resistance design of the positive pole and the case, the possible risk of internal short circuit can be quickly identified by monitoring the voltage of the pole and case, and the internal short circuit monitoring of the battery cell can be realized from the system level.

Leading the way in electric heavy truck lifepo4 battey

As commercial vehicles for operation, heavy trucks pay special attention to economic issues throughout their life cycle. Taking a fuel heavy truck tractor as an example, the total operating cost of its five-year life cycle is about 2.3 million yuan, while the cost of a rechargeable heavy truck is about 1.85 million yuan. Compared with fuel heavy trucks, the operating costs of rechargeable heavy trucks can be reduced by about 20%.

But what cannot be ignored is that the current life of traditional fuel heavy trucks can basically reach 10 years, while rechargeable heavy trucks can only last about 5 years. The main reason is that the battery life is not enough. At present, the battery system life of electric heavy trucks is only 3,000 to 4,000 times. The full life cycle cost is higher than that of fuel vehicles. The cost is relatively high for operators, which is one of the main obstacles to the electrification of heavy trucks.

REPT's 324Ah lifepo4 battery is designed for electric heavy trucks. Not only does its service life on the commercial side increase to 7,000 times, but after completing the mission of the commercial vehicle, the gradient utilization and energy storage application side of the battery can still release more than 3,000 times of regeneration value. The entire life cycle cost of electric heavy trucks will be significantly reduced.

In addition, “Compared with the previous generation product, the full life cycle cost of the 324Ah lifepo4 battery is expected to be reduced by 20%.”

Super performance advantages + reliable cost control capabilities are the necessary prerequisites for a new technology to be recognized by the market. Another crucial necessary condition is "mass production capability", which is related to whether the product can be "sold". Otherwise, even if the technology is established, it will be nothing more than talking on paper.

The REPT 324Ah lifepo4 battery cell took two years to develop and will be mass-produced in Q4 2023. To date, the cumulative shipment volume is nearly 3GWh, and the annual production capacity can reach more than 12GWh.

With the triple blessing of performance advantages + cost control + mass production capabilities, it is natural for REPT's 324Ah batteries to have many customers pay for them. Including the two car companies mentioned above that have begun mass supply, the number of announcements supporting REPT commercial vehicle series batteries has exceeded 60 models, including Dayun, Sinotruk, Shaanxi Heavy Duty Truck, Shaanxi Automobile, Liuzhou Automobile, First-class car companies such as Hongyan and Qingtuo Heavy Industry.

On the one hand, it is technological innovation and cost reduction, and on the other hand, it is mass production and supply. REPT's 324Ah lifepo4 battery cell undoubtedly has a super buff, which will greatly improve the performance and operating efficiency of electric heavy trucks, marking a major change in the pattern of the electric heavy truck industry.

Continuing to broaden its horizons, REPT has strong and sufficient customer channels - Qingshan Industrial has a very large demand for electric heavy trucks. On the one hand, it ensures the true accuracy of the 324Ah lifepo4 battery cell application data, and on the other hand, it also leads REPT in the future. The heavy truck battery cell market has laid a solid foundation.

Next, REPT will continue to focus on the battery life, cost and other pain points of electric heavy-duty trucks, and further upgrade to an ultra-long cycle life of 10,000 cycles based on the existing 7,000 cycles. At the same time, the energy density of battery cells will be continuously improved to reserve more cargo weight for commercial vehicles and further reduce operating costs.

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |