|

Product Details:

|

| Nominal Capacity: | / | Nominal Voltage: | / |

|---|---|---|---|

| Internal Impedence: | / | Operating Votage: | / |

| Dimension: | / | Battery Weight: | / |

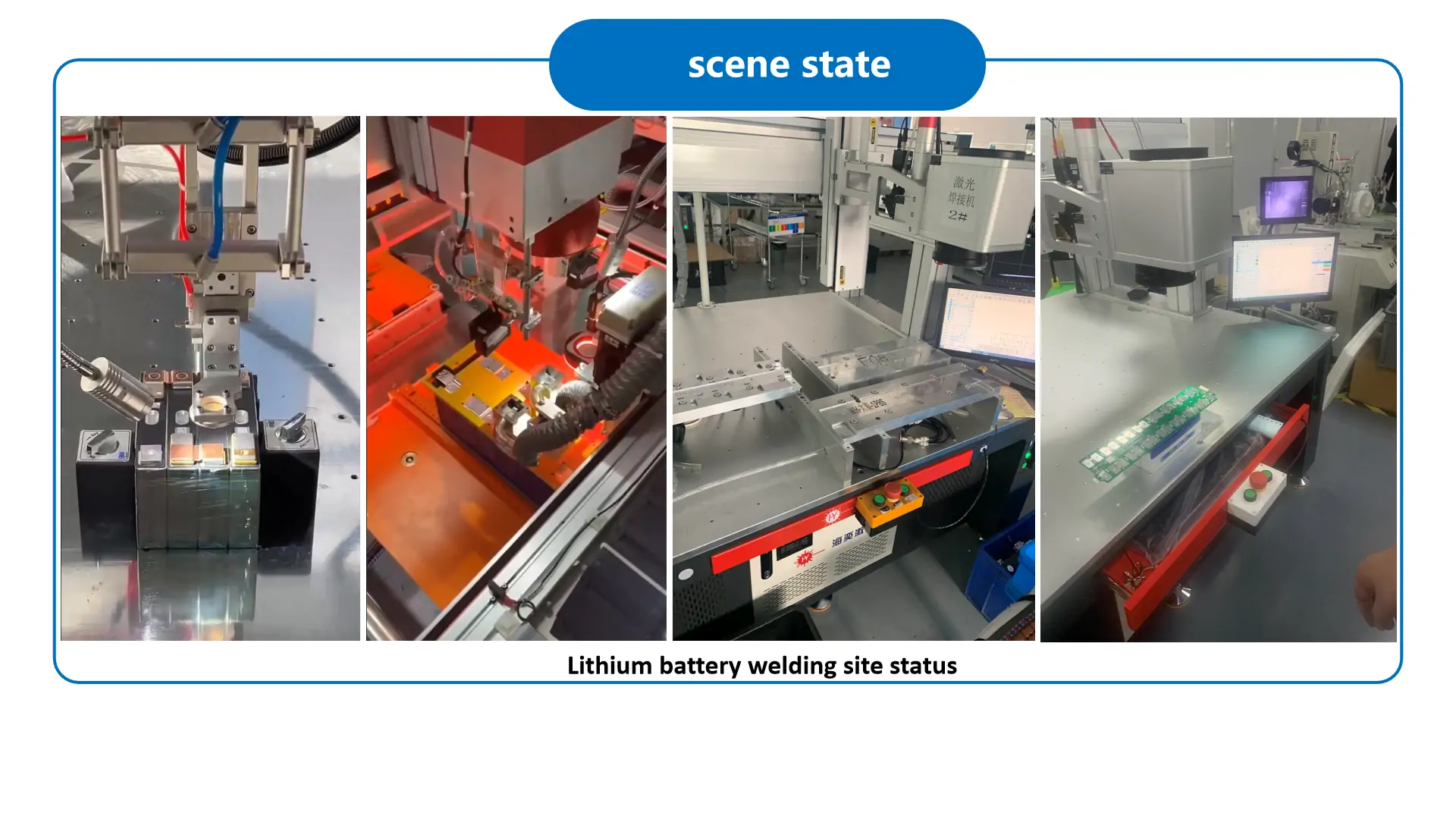

Introduction to Power Battery Welding

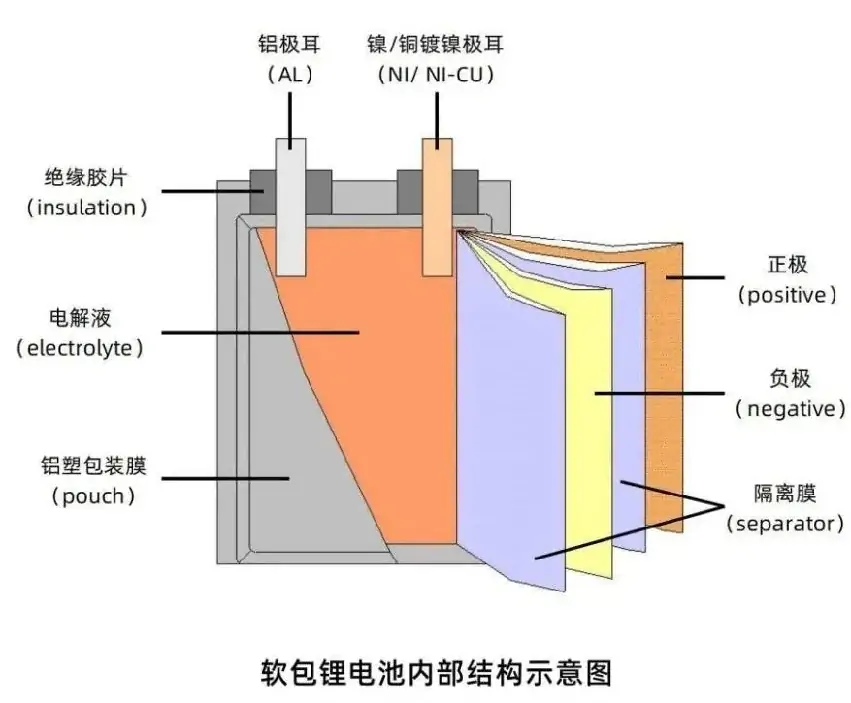

Power batteries mainly include square batteries, cylindrical batteries and soft pack batteries, square aluminum shell power batteries have become the main direction of domestic lithium manufacturing and development due to their simple structure, good impact resistance, high energy density, large single capacity, and many other advantages.

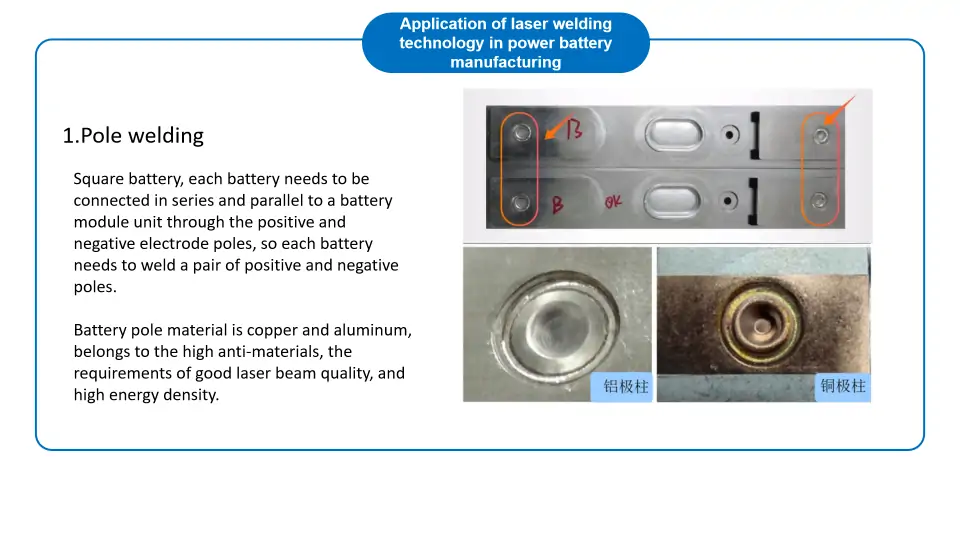

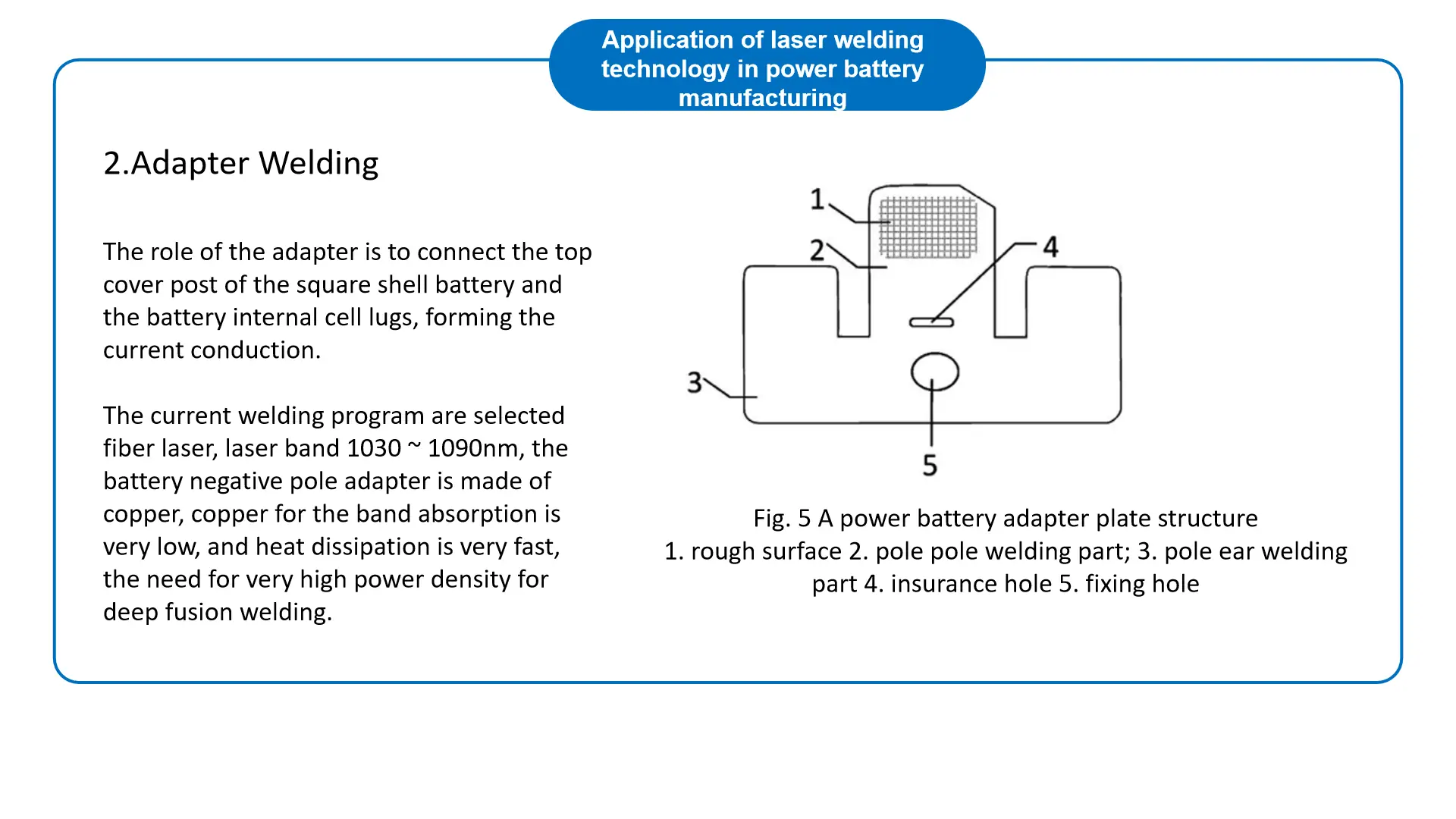

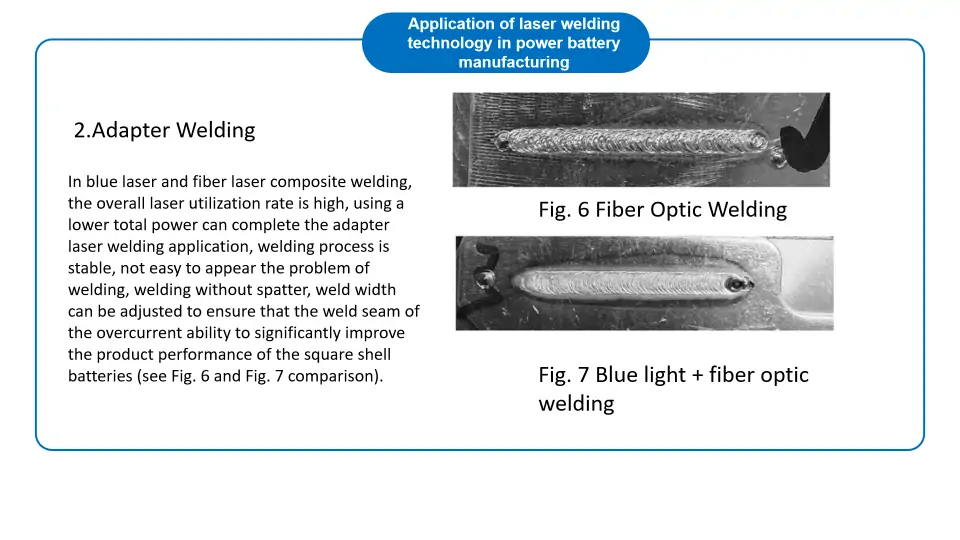

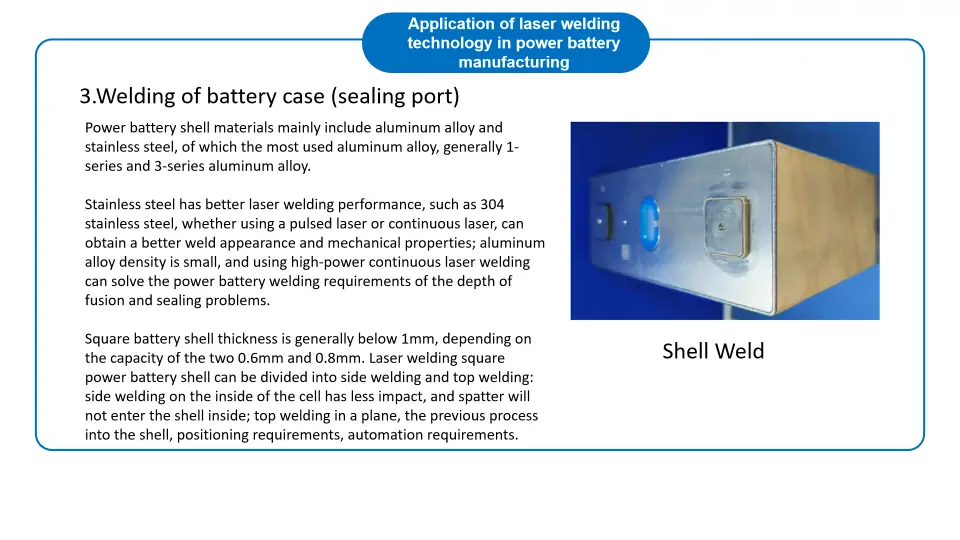

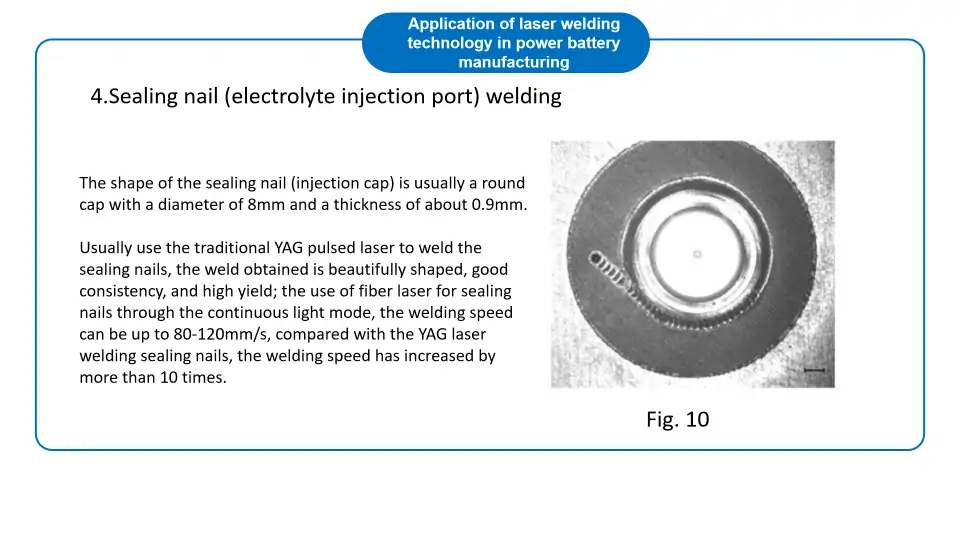

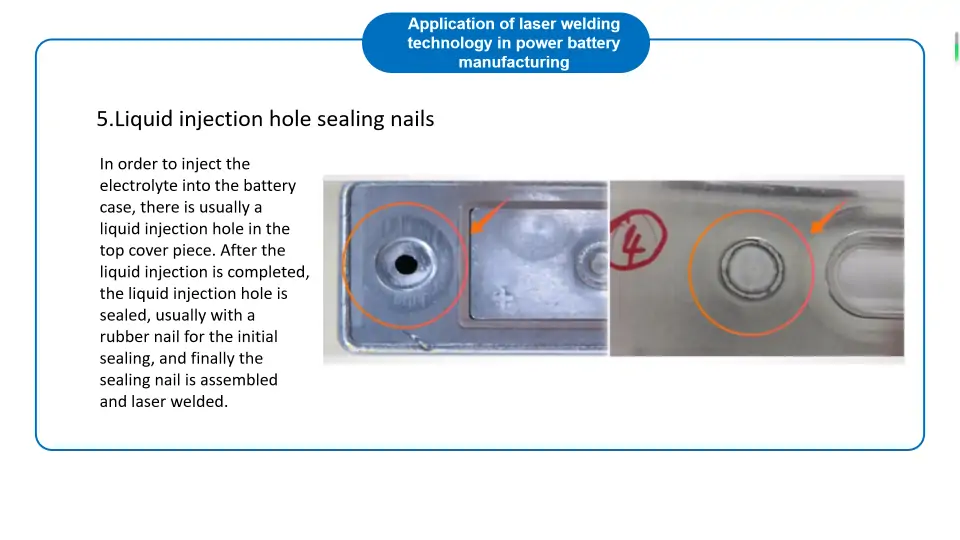

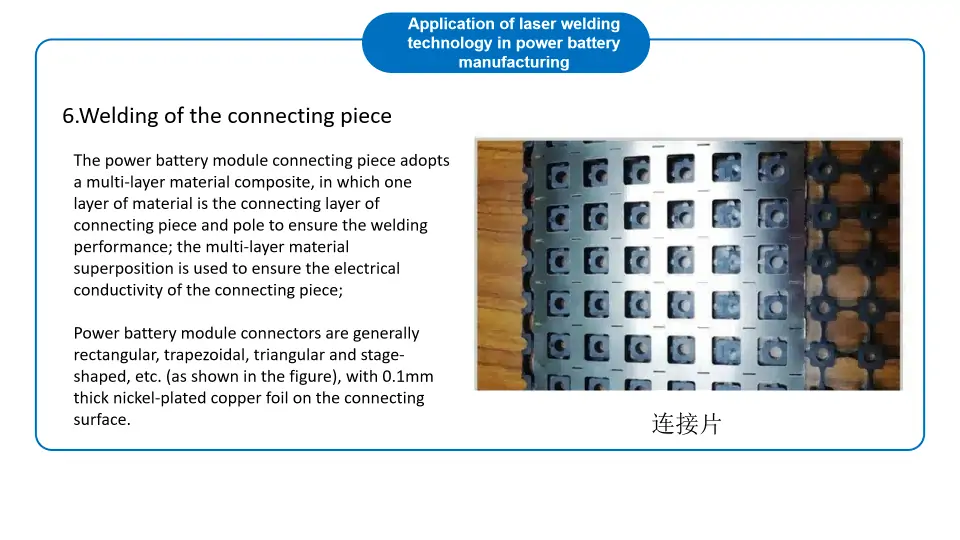

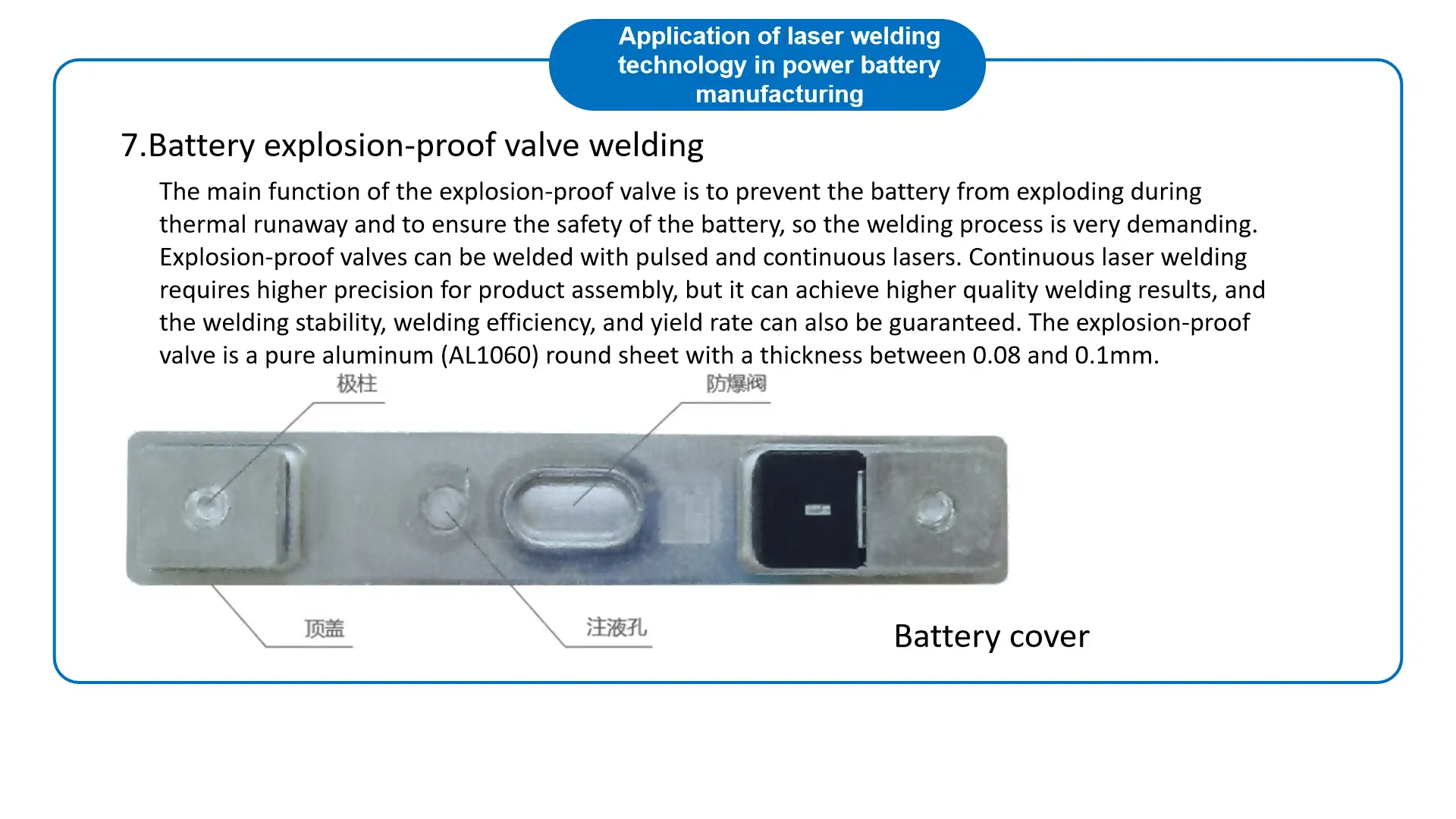

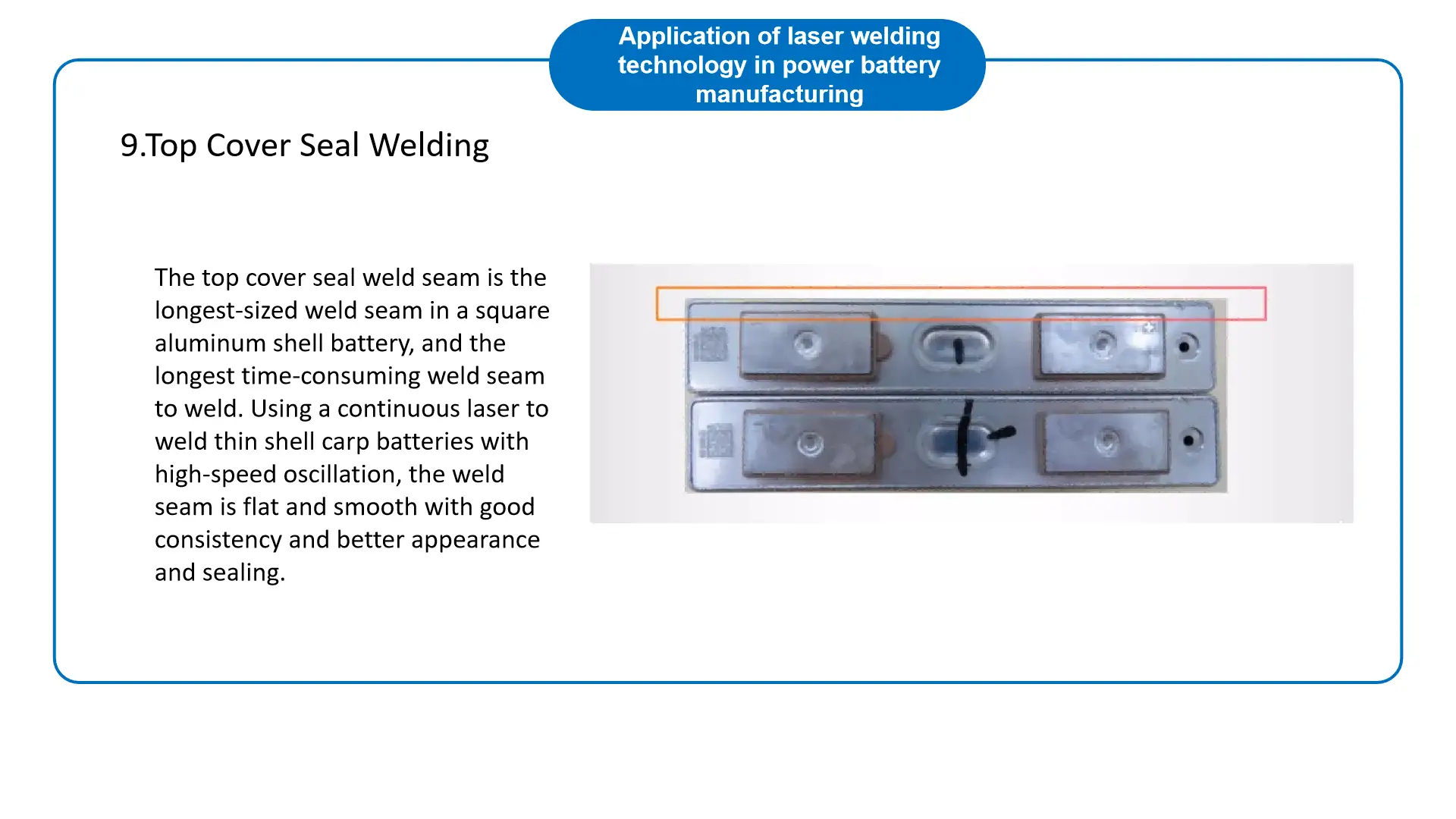

The main parts that need to be laser welded in the manufacturing process of a single battery include a pole, adapter, sealing port, electrolyte injection port, injection hole sealing nails, connecting piece, explosion-proof valve, flip-flop, top cover sealing, and so on.

Flexible pack battery mainly includes positive and negative lugs connected in series, positive and negative lugs welded with copper converging piece, and multi-layer negative aluminum and copper converging piece welding. The thickness of copper lugs is generally 0.2-0.5mm, aluminum lugs are generally 0.2-0.6mm. commonly used single-mode fiber laser lens welding.

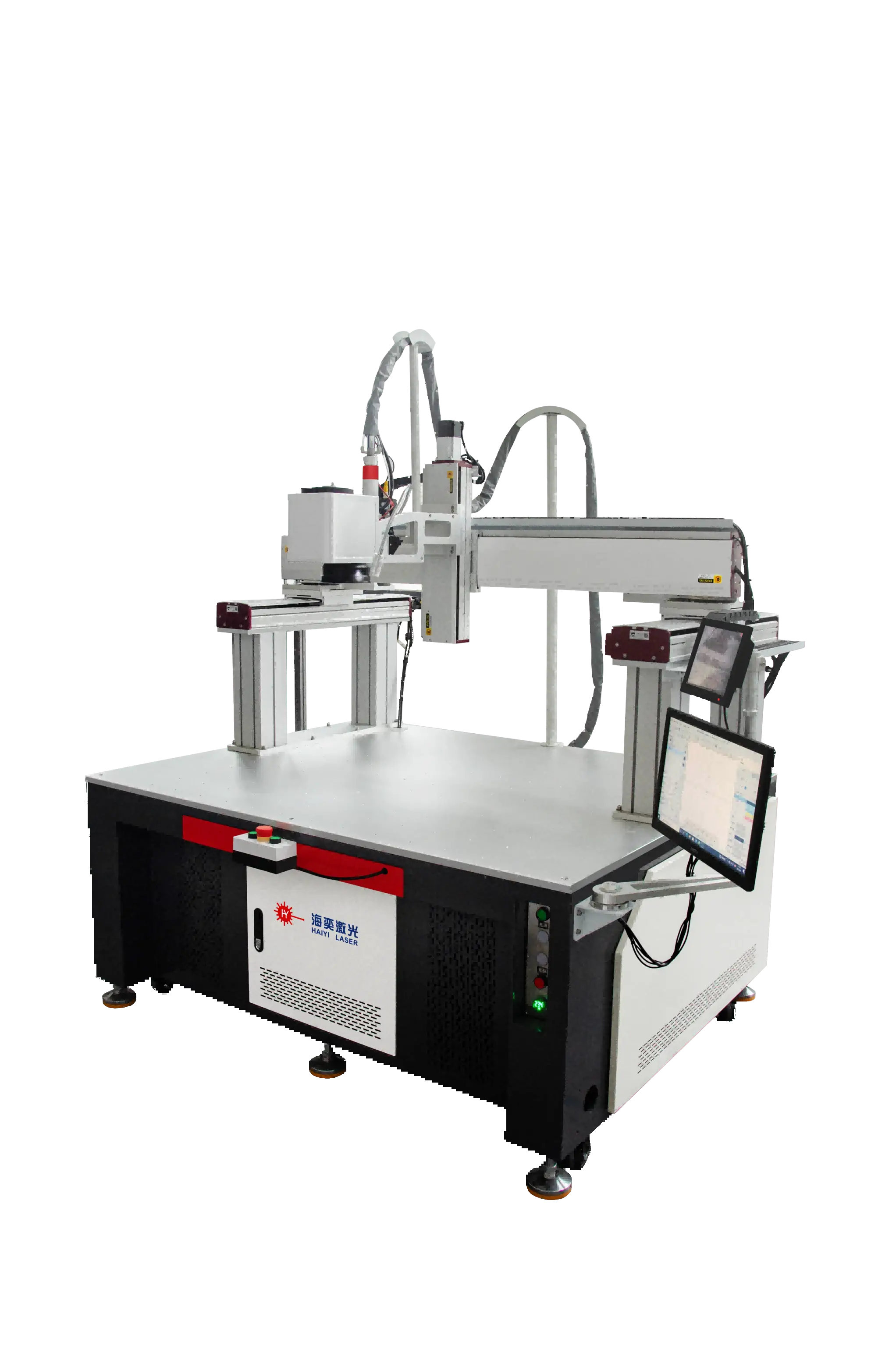

Vibrator-type laser welding machine style

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |