The power battery industry’s involvement in fast charging technology continues to escalate. On July 4, the SVOLT Supplier Summit was held in Changzhou, Jiangsu. At the meeting, SVOLT released 4C, 5C, and 6C products for PHEV and BEV respectively.

In the field of PHEV, large power has become standard, and ultra-fast charging has become a new demand. Following the release of the second-generation hybrid-specific dagger battery last year, SVOLT this time brought the "800V hybrid ternary dragon scale armor" battery.

As the name suggests, the 800V hybrid ternary dragon scale battery is suitable for the 800V platform architecture, supports ultra-fast charging, and can reach a charging rate of up to 4.2C. This product will be SOP in July 2025.

According to reports, compared with the traditional PHEV battery pack, the 800V hybrid ternary battery pack has achieved a 20% increase in volume utilization. Coupled with the energy density of 250Wh/kg, it can provide 55-65kWh power selection space for PHEV models. , bringing a pure electric range of up to 350km. This has reached the endurance level of many pure electric vehicles. In addition, this product also reduces the unit cost by 5%.

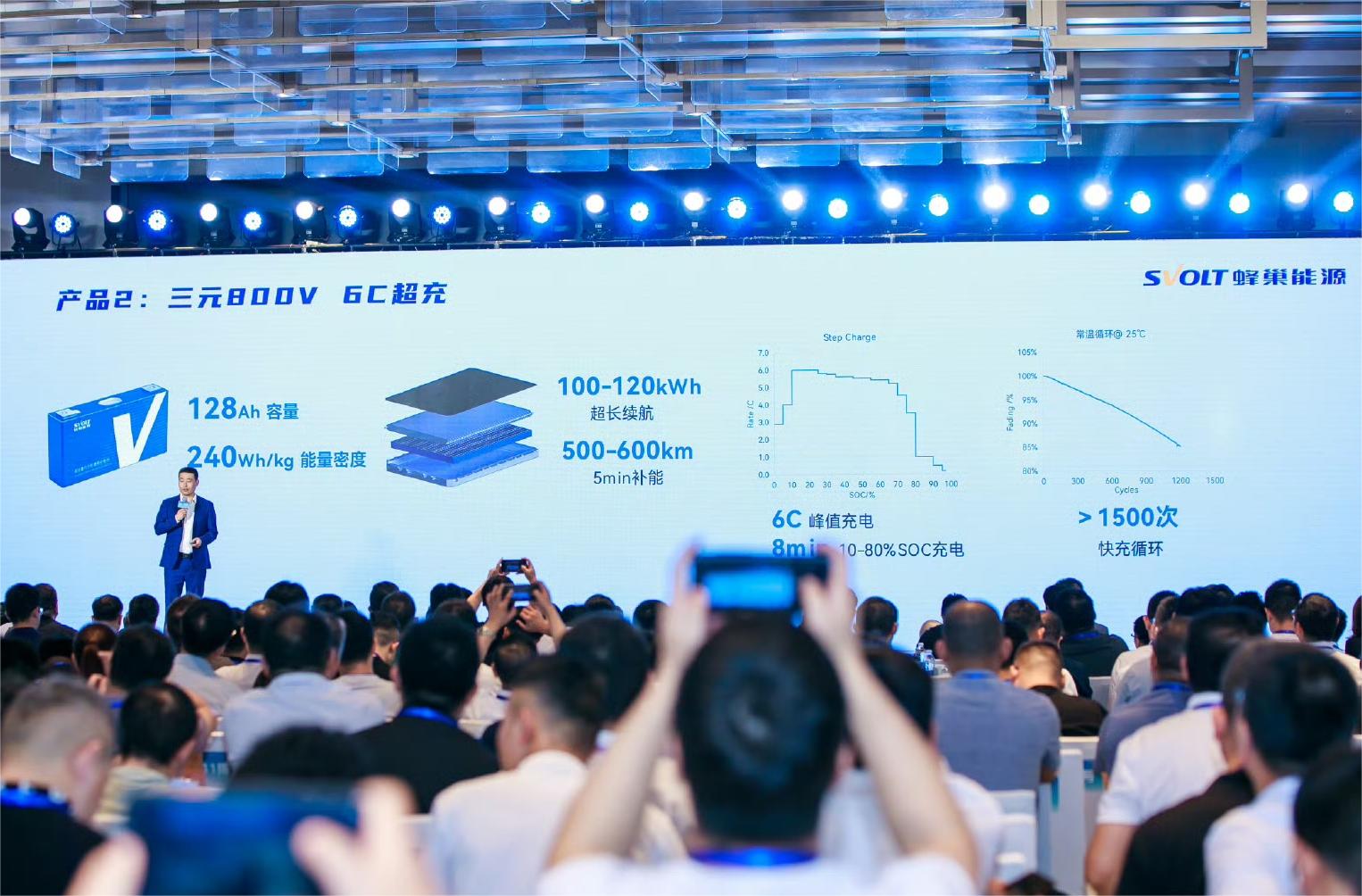

In the BEV market, which has higher charging speed requirements, SVOLT has brought two fast charging products.

The first is a dagger 5C supercharged battery based on lifepo4 battery. This product has an energy density of 185Wh/kg, a maximum charging rate of 5C, can complete 10%-80% energy replenishment in 10.5 minutes, and has a cycle life of more than 2,000 times. The product will be launched in December this year. Monthly SOP, and then choose the opportunity to go public.

The other is a 6C supercharged battery based on ternary lithium battery. 6C has become a battleground for battery companies. SVOLT's 6C supercharged battery has an average charging rate of 5.2C in the 10%-80% SOC range, the highest peak rate can reach 6C, and the energy density has reached 185Wh/ kg. This product can be applied to the 900V high-voltage architecture to be launched by car companies. It not only takes into account the ultra-long battery life, but can also charge for 5-7 minutes, increasing the battery life by 500km.

Honeycomb’s overcharging products are all based on lamination technology. Yang Hongxin, chairman of SVOLT, said that the lamination process is more suitable for fast charging, because fast-charging batteries consume electrolyte very quickly, and the loss of electrolyte will affect the battery life, while lamination can store 2% more electrolyte than winding.

In addition to releasing new products, SVOLT also shared the company's cost reduction strategy and operating conditions.

SVOLT's cost reduction strategy has also been significantly improved. For example, SVOLT uses a three-dimensional porous raw material negative electrode, which can reduce the cost of the negative electrode by 15%; using high-strength composite coating technology, it can reduce the cost of the separator by 25%.

Coupled with the manufacturing process of the cell cover, the welding of steel and cold plates at the battery system level, and the blister process, the cost in each link is generally saved by 10%-30%, which brings a comprehensive impact to SVOLT. Significant cost reduction.

Yang Hongxin also said that the third-generation "flying stack" technology has reached a lamination speed of 0.125s, which has also significantly improved production efficiency. The GWh equipment investment of the flying stacking process is now lower than that of the winding process.

Based on the improvement of the manufacturing process, SVOLT's manufacturing costs have dropped by 40%, labor costs have dropped by 15%, and the yield rate of the stable production line has reached 96%. In 2024, SVOLT aims to reduce costs on direct materials by 10%.

Yang Hongxin showed the results of SVOLT in the first half of the year: the total shipment volume of power batteries and energy storage batteries was nearly 10GWh, a year-on-year increase of more than 150%, and the revenue was close to 7 billion, with a year-on-year growth rate of 110%.

SVOLT has increased its efforts to expand overseas customers. According to reports, the company's overseas customers accounted for 28.6% of shipments in the first half of the year, and both Stellantis and BMW mini have begun large-volume supply. In the second half of the year, more than 10 new cars equipped with SVOLT batteries will be launched.

Rolling technology, rolling products, and the ability to reduce costs are SVOLT’s current strategy and a must choice for every battery factory. In 2024, the involution of the new energy vehicle industry chain has entered a white-hot stage. Before more fierce competition arrives, who can have a more stable technical level and stronger cost reduction capabilities will become the key to survival.

Next:CATL officially launches commercial power battery brand - 4C overcharging and 500km live range

Previous:4pcs winston 1000ah battery ship to New Zealand

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |