Recently, CATL held a super hybrid battery brand and new product launch conference and launched the CATL Freevoy super hybrid battery.

High performance: Pure electric range is 400km+, and it also has 4C super charging. It can charge for 10 minutes and replenish energy for more than 280km.

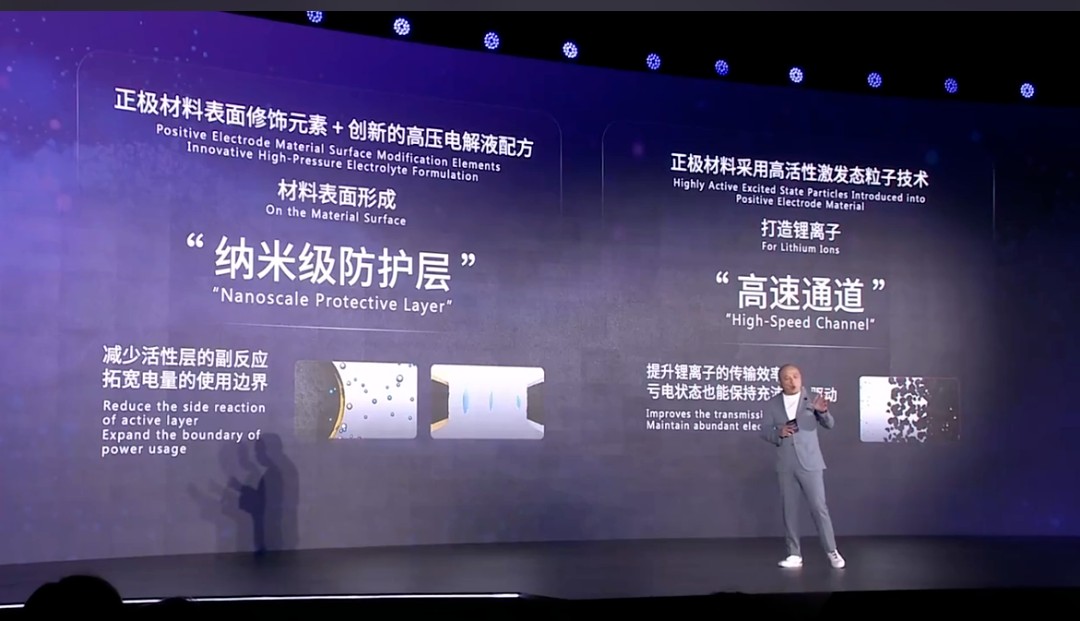

Material innovation: Positive electrode surface modification elements + innovative high-voltage electrolyte formula form a "nano-level protective layer" on the surface of the material, reducing side reactions in the active layer and broadening the usage boundaries of electricity. Highly active excited state particle technology is used to create a "high-speed channel" for lithium ions and improve the transmission efficiency of lithium ions.

Modeling of battery charge and discharge polarization characteristics: can accurately predict the battery's discharge capacity in the future and the next working condition, power prediction + power closed-loop control model, create a multi-level battery power prediction control strategy, and improve power performance again by 20 %. Based on tens of millions of vehicle usage scenarios, multi-dimensional modeling of battery characteristics is built to build an advanced SOC full-scenario model, improving SOC control accuracy by 40%. Material innovation combined with BMS intelligent algorithm optimization further reduces the SOC threshold for range extender and fuel engine intervention, and the pure electric power usage efficiency increases by another 10%.

Sodium ion battery application: Using the integration technology of AB battery system, sodium-ion batteries and lithium-ion batteries are integrated into the same battery pack, and the sodium-ion batteries are arranged in the low-temperature area of the pack, thus breaking the low-temperature bottleneck of the system and increasing the low-temperature battery life by 5%. . The requirements for BMS are high.

Low-temperature performance: The application of sodium-ion batteries to Freevoy batteries has achieved a breakthrough in being able to be discharged in extremely cold environments of minus 40 degrees. It also ensures that it can be charged at minus 30 degrees and can still provide electricity at minus 20 degrees. Strong power output is no different from normal temperature.

Three major technological innovations in sodium ion electromagnetics:

①Relying on the integration technology of CATL AB battery system, sodium-ion batteries and lithium-ion batteries are integrated into the same battery pack. The sodium-ion batteries are arranged in the low-temperature area of the pack to break the low-temperature bottleneck of the system and help increase the low-temperature battery life by 5%. Lithium-ion batteries are It not only makes up for the shortcomings of low energy density of sodium-ion batteries at this stage, but also takes advantage of its good low-temperature performance;

②Combined with the characteristics of sodium-ion batteries, it is used as an accurate SOC detection standard in the AB system to assist in calibrating the lithium ion battery power, helping to improve the overall control accuracy of the system by 30%, and the pure electric cruising range can be increased by more than 10 kilometers;

③Finally, regarding the battery management system and BMS software strategy, CATL has developed a technology for accurately calculating BMS power in the full temperature domain in view of the differences in low-temperature performance of lithium-sodium batteries, enabling targeted calculation of different chemical systems in all-weather scenarios. Partition management effectively solves the problem of power prediction distortion or power performance upgrading in harsh environments of high and low temperatures.

High reliability:

①Consistency: Very stringent requirements are put forward for battery consistency. Only when the performance parameters of each cell in the battery pack are highly consistent and balanced during the charge and discharge process can optimal battery performance be achieved. The realization of this requirement cannot be achieved without our extreme manufacturing and zero-carbon smart factories. The production line is equipped with more than 300 image detectors and A!'s detection system, exceeding 6,800 quality control points, and has accumulated the most comprehensive database in the lithium battery industry, covering nearly 1 trillion battery-related big data to ensure High consistency of battery cells.

②Production process: In the source process of production and manufacturing, we adopt the industry's most advanced cyclone pulping system, which can evenly disperse micron-sized particles in the slurry to form a stable suspended particle slurry. At the same time, at the key coating station, we independently developed the industry's original intelligent extrusion coating system. By realizing online surface density detection and closed-loop feedback, millisecond-level response speed and micron-level control accuracy are achieved. On a micron-thick copper-aluminum film running at a speed of 120 meters per minute, Yin and Yang-level coatings can be evenly coated, and the accuracy of thickness control can be plus or minus 1%, which is one micron.

High security: A multi-level security system has been constructed, covering all aspects of battery development, design, manufacturing and testing.

①Battery development and design: During the battery development and design process, in addition to the upgrade of the material system, the structure of our products was also upgraded from NP1.0 without heat diffusion to NP2.0, pioneering the technology of active isolation of smoke and high-voltage systems. It further improves the user's safety experience under extreme conditions.

②Battery manufacturing: In the battery manufacturing process, relying on the extreme manufacturing capabilities of the Lighthouse Factory, we have successfully reduced the cell defect rate to one part per billion, or PPB level.

③Battery testing: In terms of battery testing, we have conducted more than 400 verification tests at multiple levels, dimensions, and scenarios from materials, cells, modules, BMS to battery packs to ensure the safety of our products. Freevoy super hybrid batteries passed the extreme gun test and the extreme plug test.

High value: At CATL, long life is only a standard feature of batteries, and batteries that help us make money can be called excellent batteries. Freevoy super hybrid battery has excellent energy density, including charging and discharging speed, and cycle life, making it a tool to create economic benefits. By connecting to the power grid through B2G technology, the battery becomes a large mobile power case, realizing two-way energy interaction between the battery and the power grid. On the one hand, batteries can participate in the power regulation of the grid and contribute to the stable operation of the grid. On the other hand, this technology can also create additional value for users. For example, users charge during the valley phase and discharge during the peak phase, earning the price difference between the peak and valley phases of electricity.

Assuming that CATL Freevoy super hybrid battery user charges during the off-peak period at night on weekdays, and can respond to the peak discharge demand of the office building through a two-way charging pile in the company's parking lot during the day, during the battery's full life cycle , a total of about 33,000 kilowatt-hours of electricity can be sent to the power grid in reverse direction. According to the peak-to-valley electricity price difference in the Pearl River Delta, the electricity price per kilowatt hour is about 0.8~0.9. Calculated based on this difference, the income can exceed 20,000 yuan.

Implemented customers: Ideal, Avita, Deep Blue, Qiyuan, Nezha, etc. At the same time, nearly 30 hybrid models from Chery, SAIC, Geely, GAC, Lantu, and BAIC will be equipped with Freevoy super hybrid batteries in the future.

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |