Recently, CATL held a grand new product launch conference in Shanghai and officially launched its highly anticipated Bedrock Chassis. As a battery-centric CIIC integrated intelligent chassis, Bedrock Chassis focuses on intelligence and safety, aiming to provide consumers with an efficient and safe travel base.

According to Yang Hanbing, managing director of CATL (Shanghai) Intelligent Technology Co., Ltd., the upper body of a vehicle built on this chassis absorbs 15% of the collision energy, while the more robust CIIC chassis can absorb more than 85% of the collision energy of the entire vehicle.

In the collision test of CARI, the test vehicle equipped with Bedrock Chassis was able to avoid fire and explosion in a 100% frontal collision at a speed of 120km/h. What is even more amazing is that in the 120km/h frontal column collision test, Bedrock Chassis also demonstrated excellent safety performance. The bearing area of a column collision is only 1/6 of that of a head-on collision. The damage caused by the collision at the same speed will only be more serious. However, under the protection of Bedrock Chassis, the test vehicle successfully passed this harsh test. The high voltage was disconnected at the moment of collision, and it still did not catch fire or explode after being stationary for 12 hours.

The reason why Bedrock Chassis can achieve unprecedented safety is due to CATL's three major technological innovations in structural safety, battery cell safety, and high voltage safety.

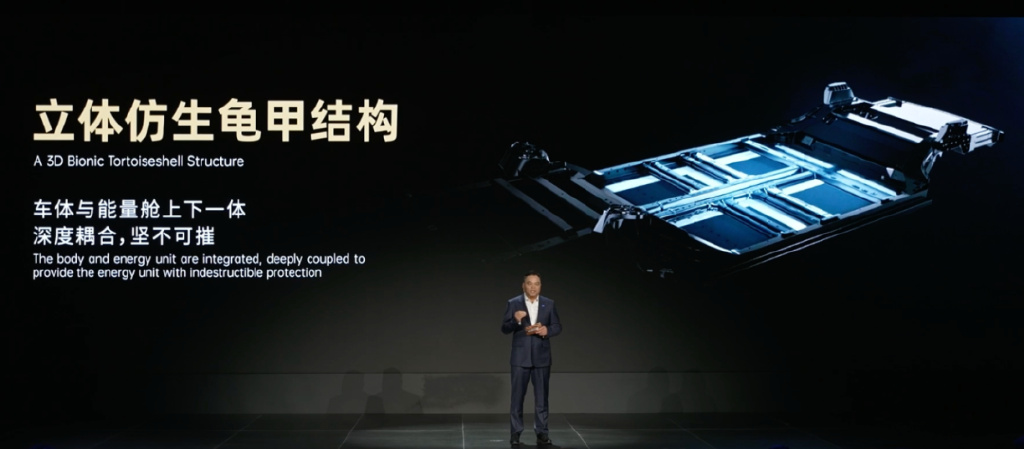

In terms of structural safety, Bedrock Chassis adopts a "three-dimensional bionic tortoise shell structure", and the body and energy cabin are integrated from top to bottom to form a solid barrier.

At the same time, it also draws on the aircraft carrier-style arresting structure, which can gradually slow down the vehicle when it collides, reduce the intrusion speed, and further protect the safety of passengers. In addition, the application of submarine-grade hot-formed steel and aerospace-grade aluminum alloy has greatly improved the supporting strength of the chassis, allowing the vehicle to maintain structural integrity in extreme situations.

In terms of battery cell safety, Bedrock Chassis uses CATL's latest battery technology to achieve safe battery application from the source. For the battery cell, Bedrock Chassis uses a high-toughness insulating film for optimization, so that it can absorb part of the collision energy in the structure, thereby reducing the deformation of the battery cell in a collision accident and the resulting thermal runaway risks. In addition, the application of the inverted battery cell design allows high-temperature gases to be discharged from the bottom when thermal runaway occurs, further reducing the temperature disturbance to other components. At the same time, Bedrock Chassis is also equipped with an intelligent battery management system (BMS), which can monitor the status of the battery pack in real time and prevent potential safety hazards such as battery overheating, overcharging, and over-discharging.

High-voltage safety is an important part of the safety field of new energy vehicles. Bedrock Chassis achieves the fastest high-voltage power-off in the industry. At the moment of collision, the system will cut off the high-voltage circuit within 0.01s and complete the release of residual high-voltage electrical energy within 0.2s, thereby reducing the risk of battery pack fire and explosion.

In addition to excellent safety, Bedrock Chassis also has good performance in terms of endurance and intelligence. According to official information, the endurance of models using Bedrock Chassis can still easily exceed 1,000km, and the intelligence supports L3-L4 driving assistance systems, which can support wire-controlled steering, wire-controlled braking, and full-wire control and full-redundant safety design.

At the press conference, Avita, as the first brand to apply this technology, signed a contract with Contemporary Amperex Technology, a subsidiary of CATL. The two parties deepened their cooperation around the Bedrock Chassis to create a safer and higher-quality travel experience for users.

Next:6V vs 12V Battery: Which Voltage is Best for Your Needs?

Previous:16pcs 3.2V 320Ah REPT LiFePO4 Battery Cells Ship to South Africa

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |