CALB Chairman Liu Jingyu was invited by the World New Energy Vehicle Conference (WNEVC) to share CALB's power battery technology and product innovation, and unveiled CALB's rapid development in the lithium power battery market.

The latest data released by market research agency SNE Search shows that in July this year, the total global power battery installed capacity was approximately 57.7GWh. Although it increased by 43.2% year-on-year, it fell by 12.4% month-on-month.

Against this background, CALB still delivered the most eye-catching answer: with a global power battery installed capacity of 3.4GWh, it ranked among the top five in the global power battery installed capacity rankings that month.

The first look is Panasonic's 3.9GWh, but Panasonic's fell 9.3% month-on-month. The lower look is SK On's 2.8GWh, but SK On also fell 6.7% year-on-year. Even CATL, BYD and LG New Energy experienced month-on-month declines, with declines of 18.4%, 2.0% and 29.7% respectively.

CALB achieved a year-on-year increase of 94.6% and a month-on-month increase of 21.4%. It is the only company among all TOP10 companies to achieve a month-on-month increase!

CALB, which has jumped from seventh place in the global ranking of power battery installations to the top five in the world, and whose power battery installations are still growing, has become the most beautiful scenery in the global power battery market.

Behind CALB's rapid progress is the continuous advancement of the company's technology and products. Starting from high-voltage technology, to full-tab lamination technology, OS technology, "top-flow" large cylindrical battery technology, etc., CALB has innovatively developed Each new technology and corresponding product development paths.

CALB Chairman Liu Jingyu’s sharing on WNEVC also attracted more attention.

Composite metal anode, energy density 600Wh/Kg

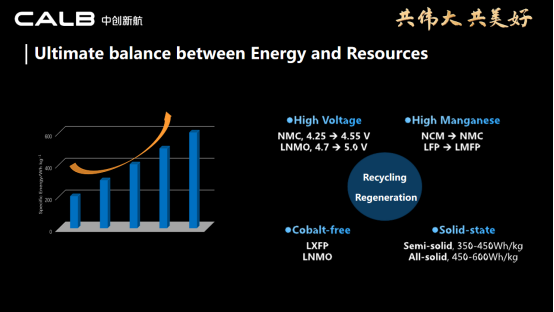

According to Liu Jingyu, CALB's research on materials and chemical systems is driven by the ultimate balance of energy and resources as an important driver of technological innovation, which is reflected in four aspects: high pressure, high manganese, cobalt-free and solid state.

High-voltage ternary lithium battery technology was launched by CALB under the concept of the ultimate balance of high energy and resources, as well as the ultimate balance of high energy and safety. This innovation has made a substantial contribution to the development of the lithium battery industry.

CALB is the first company to increase the energy density of medium-nickel 5 series products to the equivalent level of high-nickel 8 series products, and is the first to use high-voltage 5 series products to achieve a 600km range. After iterative upgrades, the 6-series high-voltage products launched by CALB can reach the level of 300Wh/Kg and support a battery life of more than 1,000km.

Liu Jingyu said that with the advancement of high-pressure technology, lower-cost, environmentally friendly manganese will play an increasingly important role. The chemical system of medium-nickel and low-cobalt layered ternary materials with a manganese content of more than 30% and phosphate materials (LMFP) and spinel materials (LNMO) with a manganese content of more than 70% will become high-specific energy, high safety, A mainstream solution with efficient resource utilization and low cost.

It is reported that in order to meet the demand for higher energy density, CALB developed a battery using lean liquefaction technology and an energy density of 350Wh/Kg. In acupuncture experiments, the battery core was pierced without catching fire, and the thermal safety performance of the battery core reached a level comparable to that of medium-nickel ternary batteries; Batteries using semi-solid-state technology can have an energy density of 450Wh/Kg, which is expected to achieve better thermal safety performance; all-solid-state battery technology using composite metal anodes can have an energy density of 600Wh/Kg, showing higher safety performance. At the same time, the cycle life is greatly improved.

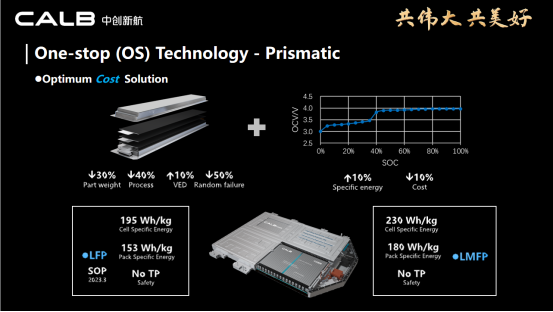

Less is more, OS minimalist design and extreme manufacturing

In the process of exploring the ultimate cost solution, CALB focuses on the high integration of design and manufacturing. Starting from the underlying functions of the product and basic technical principles, it reconstructs product design and manufacturing process, and proposes the One-stop design concept, that is: function The high degree of integration simplifies product design, manufacturing process, and production equipment, reduces the complexity of products and processes and the intensity of unit fixed asset investment, and achieves high stability, high reliability and low cost of large-scale production. And developed a series of key technologies covering new structures, new equipment, and new processes.

The first-generation OS cells currently mass-produced by CALB have simplified the number of parts by 25%, the number of processes by 40%, and the corresponding manufacturing costs have been reduced by more than 10%. Liu Jingyu said, "OS batteries perfectly take into account the special requirements of modular system integration. The modular-free CIR battery system we have mass-produced has reduced the number of parts by more than 10% and simplified the manufacturing process by 25%. It is the first Increase the energy density of the LFP battery system to 153Wh/Kg."

Currently, lithium iron phosphate battery has become the mainstream in ranges within 700km. Liu Jingyu said that with the development of LMFP technology, the energy density of CALB OS batteries will reach 230Wh/Kg, and the energy density of LMFP battery system will exceed 180Wh/Kg, while the cost will be further reduced by 10% compared with the current LFP. above. "We believe that LMFP-CIR technology provides the best systematic solution for low-cost applications and will become the mainstream in the range of 800km or less."

"Top-notch" large cylinder, fast charging beyond 6C

Facing the high-end demand for high performance, CALB proposed the industry's first "top flow" structure and 46 series large cylinder technology.

CALB's "top-flow" large cylindrical battery adopts tab-collecting plate-cover integrated assembly and linkage welding technology to maximize functional integration. Through minimalist manufacturing, manufacturing efficiency is increased by 50%.

Compared with the "poleless ear" structure, the current flow path of the "top flow" structure is shortened by 70%, and the internal resistance of the structure is reduced by 50%, which greatly reduces the heat generation of high-power charging and discharging; the "Z" utilization rate is as high as 87.5%, and the power The core energy is significantly improved; the "top flow" design prevents the casing from serving as a flow guide component and uses stainless steel as the casing material to achieve "zero" corrosion and high reliability; the fast charging capacity exceeds 6C, which greatly relieves users' energy replenishment anxiety.

CALB believes that the "top-notch" large cylinder brings the best solution for high-performance application scenarios. It can achieve high specific energy of more than 300Wh/Kg, safety performance without heat spread, 6C fast charging experience, and higher Manufacturing efficiency and highly standardized structural dimensions.

It is understood that CALB has equipped more than 40 pure electric passenger models and more than 100 hybrid passenger models, and can be launched on all models according to customer needs; CALB has the ability to install more than one million units annually, equivalent to More than 5 million tons of carbon emissions can be reduced a year.

Liu Jingyu said that the development of CALB reflects that electrification is the right way for the automotive industry to achieve green, low-carbon, and sustainable development goals. CALB will always adhere to the concepts of green, low-carbon, and sustainable development, adhere to technological innovation, and contribute to the health of the industry. Development continues to contribute to CALB.

Next:Golden Feather lithium battery energy density exceeds 460Wh/Kg!

Previous:380pcs Winston 3.2V 300Ah lifepo4 battery to USA

Contact Person: Miss. Elsa Liu

| WhatsApp : | +8617763274209 |

|---|---|

| Skype : | +8617763274209 |

| WeChat : | 17763274209 |

| Email : | Elsa@lifepo4-battery.com |